trigalight Technologie

Mit trigalight bietet mb-microtec ag ein wartungsfreies, sehr kompaktes System mit einer minimalen Einbaugrösse, das für Sicherheit und Effizienz steht.

PRODUKTIONSPROZESS:

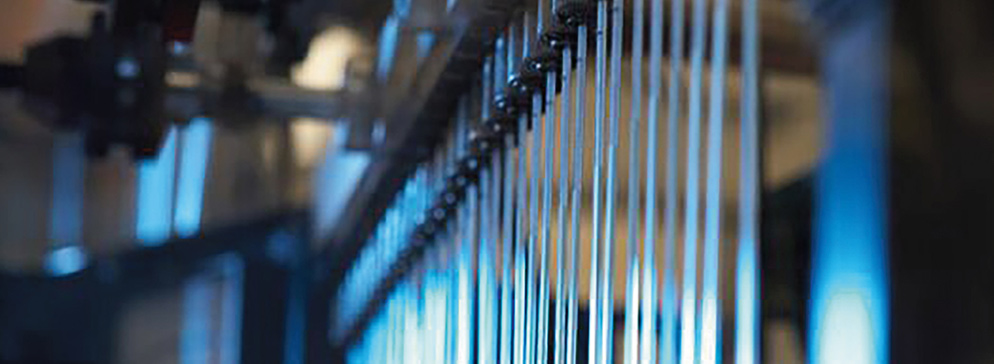

SCHRITT 1: PRODUKTION VON GLASKAPILLAREN

Grosse Glasrohre werden erhitzt und in dünne Glaskapillaren der gewünschten Dimension umgeformt. Der kleinstmögliche Aussendurchmesser liegt bei 0.30 mm und entspricht ungefähr der fünffachen Dicke eines menschlichen Haares.

SCHRITT 2: BESCHICHTUNGSPROZESS

Die Innenseite der Glaskapillare wird mit einem lumineszierenden Pulver (Zinksulfid) beschichtet. Jede Farbe ist möglich. Am häufigsten wird die Farbe Grün eingesetzt, da sie vom menschlichen Auge als am hellsten wahrgenommen wird.

SCHRITT 3: EINFÜLLUNG VON TRITIUM

In einem durch mb-microtec entwickelten Verfahren werden die Glaskapillaren mit Tritiumgas gefüllt.

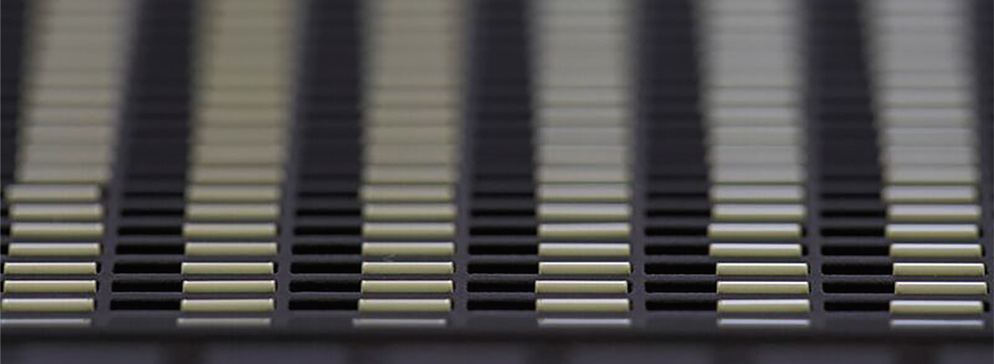

SCHRITT 4: LASERSCHNEIDEPROZESS

Die mit Tritiumgas gefüllten Glaskapillaren werden mittels einer hochautomatisierten Laserabschmelzmaschine auf die gewünschte Länge geschnitten und gleichzeitig hermetisch verschlossen.

SCHRITT 5: QUALITÄTSKONTROLLE

Jede einzelne Lichtquelle wird einer strengen Qualitäts- und insbesondere Dichtheitskontrolle unterzogen.

SCHRITT 6: ANWENDUNGEN

Je nach Anwendung werden die Lichtquellen in Aluminiumhülsen oder Kunststoffummantelungen mit einem Saphirglas verbaut oder direkt auf Zifferblätter bestückt. Unsere trigalight Produkte werden vor allem im taktischen Markt, in der Uhren-, Sicherheits-, Automobil-, Raum- und Luftfahrtindustrie eingesetzt.